When Italian Fashion Meets Israeli Tech

A worker finishes the shoes on November 4, 2016 in Padova, Italy. The consortium of Riviera del Brenta in Padova has continuously served as the home base for a number of the world’s leading specialists in luxury footwear manufacturing, including Valentino, Missoni, Alain Tondowski, Arvid Yuki Shy and Rayne London. Image by Getty Images

If you’re tired of this season’s handbag styles, why not design one yourself?

That’s exactly what Italian start-up ‘XYZBag’ hopes to deliver, with the help of Israeli technology: 3D-printed, self-designed handbags.

“XYZBag explores the power of 3D technology, while empowering the uniqueness of the individual,” CEO Annalisa Nicola told The Forward at this year’s OurCrowd Global Investor Summit in Jerusalem.

A customer simply visits the company’s website and customize a basic tote bag or clutch with a new handle, color, design or even texture, transferring her design aspirations into a digital file that can then be 3D printed and delivered to her doorstep in 30 days.

“I believe 3D printing has reached a tipping point, and it is about to go mainstream, where the 3D prototype will replace the manufacturing of the product itself,” Nicola said from the summit’s crowded Fashion Tech Plaza.

XYZBag was one of six Italian fashion tech startups in Israel on February 1 for the world’s largest annual investor conference showcasing the latest in mobility tech, drones, robotics, artificial intelligence and medtech. The OurCrowd Summit drew 10,000 people from 90 countries, including 1,000 startups and 500 multinational firms.

Image by Screenshot/Youtube

Walk around the conference hallway, and you’d see young fashion industry presenters with thick Italian accents, alongside Israeli investors, venture capitalists and tech gurus anxious to see the latest in Italian artisanship and technology.

Italian Ambassador Gianluigi Benedetti said he brings Italian startups to Israel to learn from and tap into the Israeli startup fever, aiming to connect Israeli innovation with the European marketplace.

“In this particular sector of fashion, we hope to put together Italian excellence with Israeli technology,” said Benedetti. “Our economic systems are very complimentary.”

Andrea Carpineti, the CEO of Design Italian Shoes, who lives and works in Le Marche, Italy – known as Shoe Valley – came to Israel on a mission to find an Israeli AI strategist who could help ‘Design Italian Shoes’ make intelligent design recommendations to its customers.

A DIS shoe on display. Image by Maayan Jaffe

Carpineti said that in his hometown, he was watching as premier Italian shoe artisans were shuttering their doors because they could not compete in the international marketplace.

“These are small artisans in Shoe Valley that make high-quality shoes, but they don’t even have a website, and most don’t know English,” Carpineti said.

Carpineti’s company digitized the supply chain, bringing customizable, made-in-Italy shoes direct to the international buyer through its ecommerce platform.

Using the company’s 3D configurator, a customer can choose from hundreds of models of shoes and then customize every part of it, from the material, the color, the eyelets, the laces, the lining and even the sole. There are more than 50 million combinations, including ones in which the buyer submits his name or own image to be painted on the shoe.

Image by Screenshot of DIS site

The fabrics are premium Italian label fabrics, including hand-painted and hand-brushed leather. Prices range from an average of 300 euros ($375) to as high as 4,000 euros ($5,000), “We believe in mass customization,” said Carpineti. “We have everything you can imagine.”

Other companies are less interested in customizing fashion – and more in making it eco-friendly.

Duedilatte came to Israel pitching its wildly imaginative product: The company makes the first-ever T-shirts and baby clothes made from ‘latte’, the Italian word for milk.

Founder and CEO Antonella Bellina was a textile research student. One day, she was pondering Italy’s horrible waste of more than two tons of milk annually. She tried turning casein milk protein into fiber, and it worked. From the fiber, she makes thread and then weaves it into soft-as-silk fabric.

The creamy white garments are 100 percent natural, anti-bacterial, anti-allergen and ultra-breathable. The casein produces 18 amino acids that moisturize the skin.

“The fashion industry procures a lot of pollution,” said Bellina. “The potential market for this fabric is very large – not just in the fashion industry but the medical industry, because my fabric is certified organic and good for the skin.” She dyes her clothes, all made in Tuscany, with leaves.

In Israel, Bellina said she was looking for potential investors or an Israeli business partner who could help leverage new market opportunities.

“The name Duedilatte means two ways to see the milk: you can drink it, or you can wear it,” said Bellina, as she exchanged business cards in hopeful anticipation of closing a deal with one of the dozens of prospects who crowded around her booth.

It was Bellina’s first time in Israel. And although the trip has not yet led to a new contract, she said that being at OurCrowd, and in the tech-driven startup nation, she could envision “internationalizing” her brand in a way she never considered.

“Right now I am mostly B to B, but I could see doing B to C or e-commerce,” said Bellina. “Here, I’m working on it. In Israel, I’m looking to the future.”

The Forward is free to read, but it isn’t free to produce

I hope you appreciated this article. Before you go, I’d like to ask you to please support the Forward.

Now more than ever, American Jews need independent news they can trust, with reporting driven by truth, not ideology. We serve you, not any ideological agenda.

At a time when other newsrooms are closing or cutting back, the Forward has removed its paywall and invested additional resources to report on the ground from Israel and around the U.S. on the impact of the war, rising antisemitism and polarized discourse.

This is a great time to support independent Jewish journalism you rely on. Make a gift today!

— Rachel Fishman Feddersen, Publisher and CEO

Support our mission to tell the Jewish story fully and fairly.

Most Popular

- 1

Fast Forward Ye debuts ‘Heil Hitler’ music video that includes a sample of a Hitler speech

- 2

Opinion It looks like Israel totally underestimated Trump

- 3

Culture Cardinals are Catholic, not Jewish — so why do they all wear yarmulkes?

- 4

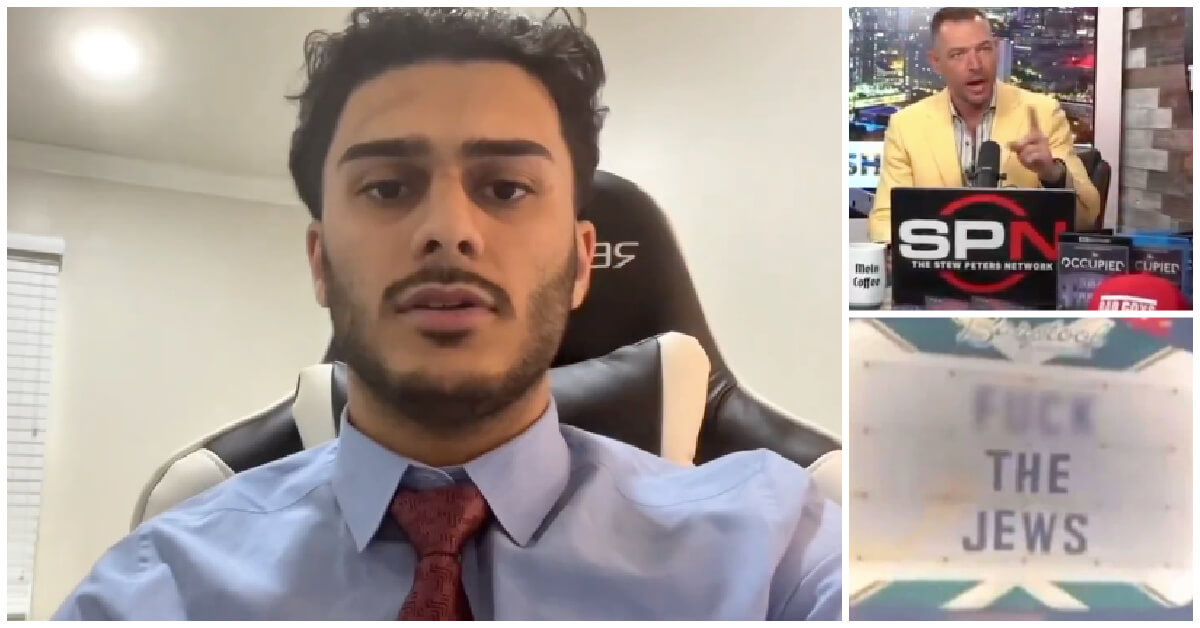

Fast Forward Student suspended for ‘F— the Jews’ video defends himself on antisemitic podcast

In Case You Missed It

-

Culture Should Diaspora Jews be buried in Israel? A rabbi responds

-

Fast Forward In first Sunday address, Pope Leo XIV calls for ceasefire in Gaza, release of hostages

-

Fast Forward Huckabee denies rift between Netanyahu and Trump as US actions in Middle East appear to leave out Israel

-

Fast Forward Federal security grants to synagogues are resuming after two-month Trump freeze

-

Shop the Forward Store

100% of profits support our journalism

Republish This Story

Please read before republishing

We’re happy to make this story available to republish for free, unless it originated with JTA, Haaretz or another publication (as indicated on the article) and as long as you follow our guidelines.

You must comply with the following:

- Credit the Forward

- Retain our pixel

- Preserve our canonical link in Google search

- Add a noindex tag in Google search

See our full guidelines for more information, and this guide for detail about canonical URLs.

To republish, copy the HTML by clicking on the yellow button to the right; it includes our tracking pixel, all paragraph styles and hyperlinks, the author byline and credit to the Forward. It does not include images; to avoid copyright violations, you must add them manually, following our guidelines. Please email us at [email protected], subject line “republish,” with any questions or to let us know what stories you’re picking up.